Selective Laser Sintering (SLS), SLS Prototype | ||

The use of selective laser sintering prototyping (commonly called SLS prototyping or 3D SLS prototyping) is ideal for product prototypes that require exceptional strength, or must closely approximate the properties of thermoplastics.

ProtoCAM is a premier selective laser sintering bureau, specializing in the creation of SLS prototypes through the use nylon, metals and elastomers. Our advanced selective laser sintering and SLS equipment allows for the rapid product prototype creation, in complex shapes and forms.

Why selective laser sintering (SLS) prototypes? In selective laser sintering (SLS), three-dimensional parts are created by fusing (“sintering”) powdered thermoplastic materials with the heat from an infrared laser beam. Thin powder layers are repeatedly laser sintered, creating the desired 3D piece based on a 3D CAD model. Selective laser sintering is an additive manufacturing sequence process, as parts gradually increase in size until they reach prescribed dimensions. In selective laser sintering (SLS), three-dimensional parts are created by fusing (“sintering”) powdered thermoplastic materials with the heat from an infrared laser beam. Thin powder layers are repeatedly laser sintered, creating the desired 3D piece based on a 3D CAD model. Selective laser sintering is an additive manufacturing sequence process, as parts gradually increase in size until they reach prescribed dimensions.SLS or SLA?

There are several key differences between prototypes created using selective laser sintering (SLS) and prototypes created with stereolithography (SLA). These include:

ProtoCAM offers clients many choices for selective laser sintering/SLS prototypes. Several popular SLS material choices include:

DuraForm

Best for functional plastic parts. Download datasheet (PDF)

DuraForm GF

Best for glass-filled functional plastic parts. Download datasheet (PDF)

Somos 201

Best for durable elastomer parts. Download datasheet (PDF)

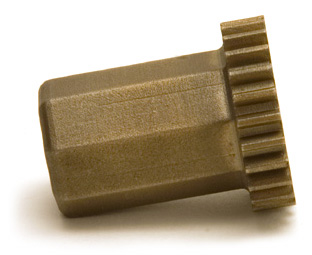

LaserForm A6

Best for metal prototypes and tooling. Download datasheet (PDF)

CastForm PS

Best for casting patterns. Download datasheet (PDF)

| ||

http://www.protocam.com/html/sls.html

Thanks for sharing. This laser kind of sintering spare parts make it worth using and even durable in long run!

ReplyDeleteSintered Components